Highly efficient CNC grinding solutions

Highly efficient CNC grinding solutions

Blog Article

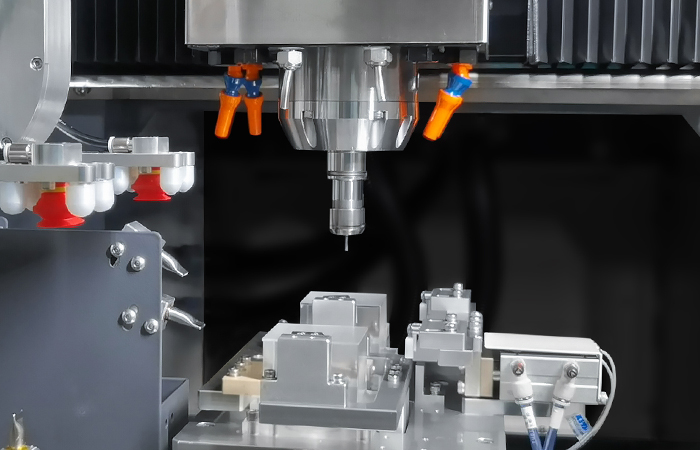

The JTGK-500F Pro CNC Grinding Center is a leading high-performance CNC grinding center designed to meet the requirements of high-precision, high-speed and high-efficiency mass production. Developed by Kejie Technology, the JTGK-500F Pro can handle a variety of difficult materials, including glass, ceramics, sapphire, silicon carbide, silicon nitride, titanium alloys and engineering plastics, and is widely used in aerospace, medical equipment, semiconductors and other industries.

Main Features

Excellent processing capabilities:

The JTGK-500F Pro has excellent dynamic processing performance and can efficiently complete precision processing tasks. Its high-speed grinding capability ensures that it can maintain extremely high production efficiency and accuracy even in complex mass production environments, especially suitable for mass processing of high-precision parts.

Automated tool management system:

The device is equipped with an efficient automatic tool library that supports fast and automatic exchange of tools of various sizes. The tool management system greatly improves production efficiency, reduces tool change time, and ensures the accuracy and consistency of each tool, suitable for long-term unattended operation.

Easy-to-operate CNC system:

JTGK-500F Pro uses a high-speed CNC control system independently developed by Kejie Technology. The operation interface is simple and intuitive, with stronger compatibility and openness, and can easily adapt to various processing needs. The human-machine interaction design greatly shortens the learning curve of operators, thereby improving the efficiency of the production line.

Flexible fourth-axis function:

The device provides an optional fourth-axis function, which can realize multi-faceted processing with one-time clamping, further improving processing flexibility and precision. This feature is particularly suitable for processing tasks that require complex geometries and high precision.

Technical parameters

Travel: X-axis 500mm, Y-axis 400mm, Z-axis 230mm.

Workbench size: 530mm × 430mm, maximum load weight 150kg.

Spindle: Power 4.5kW, maximum speed 32,000rpm, HSK E32 interface, to ensure stable high-speed processing performance.

Fast moving speed: 15m/min, cutting feed speed reaches 10m/min, greatly improving processing efficiency.

Accuracy: Positioning accuracy reaches 0.008mm/300mm, repeat positioning accuracy is 0.005mm, ensuring high consistency and accuracy of each processing cycle.

Machine weight and size: Net weight 3000kg, overall dimensions are 1550mm × 1550mm × 2250mm.

Power supply: 3-phase AC380V ±10% (50Hz), adaptable to power systems in different regions of the world.

Standard accessories

High-speed CNC controller

High-speed spindle system

AC servo motor

Precision ball screw and guide rail

Automatic tool setter

Handwheel

Spindle cooling system

Optional accessories

4-axis rotary table

Wireless probe

Oil mist collector

Voltage stabilizer

JTGK-500F Pro CNC Grinding Center not only provides users with highly reliable grinding solutions, but also provides flexible and configurable support for high-precision processing needs in various industries. Whether it is small-batch production or complex parts processing, this grinding center can help companies significantly improve production efficiency and product quality with its excellent performance and stability, and is a highly competitive choice in the field of industrial manufacturing.